*Developed jointly with the Korean company SHINWOOMESTEEL CO., LTD.

Small, Highly-efficientAluminum Melting Furnaces [ Electric ]

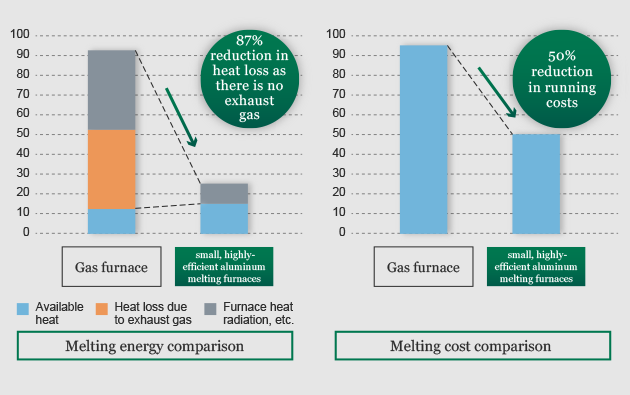

- Energy-saving and highly efficient

- Highly efficient operation due to its electric heater

Reduced energy loss due to improved heat insulation in the furnace walls

Enables one-by-one style production - Safety and work environment

improvement - Contains no hot-water distribution area as it melts individually (close at hand)

Contains no exhaust duct and produces no smoke

Able to handle a variety of materials just by exchanging the crucible - Low cost

- Reduced investment and running tests due to its simple construction

Reduced maintenance costs

Track Record

|

|

|

|---|

| SW-300 | SW-500 | SW-700 | SW-700T* | SW-1000 | |

|---|---|---|---|---|---|

| Crucible capacity (kg) |

300 | 500 | 700 | 700×2 | 1000 |

| Electric capacity (kW) |

50 | 85 | 100 | 200 | 130 |

| Melting capacity (kg/hr) |

100 | 125 | 175 | 175×2 | 250 |

| Start-up time (hr) |

3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| Dimensions (mm) |

φ1350×H1029 | φ1500×H1120 | φ1630×H1220 | φ3730×H1270 | φ1630×H1400 |

*Uses two 700kg furnaces ( Melting and retention )

Super Small, Highly-efficientAluminum Melting Furnaces [ Electric ]

Operability excellent for test runs and experiments!

High performance due to optimal coil design!

< The following data is for a 10kg furnace. We welcome inquiries for other sizes. >

High performance due to optimal coil design!

< The following data is for a 10kg furnace. We welcome inquiries for other sizes. >

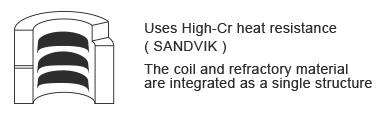

- Kanthal heating coils

- Crucible

- Improved heat conductivity due to the quality of the

material and lower sheet metal gauging (20mm→13mm) - Heat insulation material

- Nano-tech heat insulation material ( Uses Aerogel )

| Dimensions (mm) |

φ520×H410 |

| Electric power (kW/V) |

10/200 |

| Melting capacity (kg/min) |

0.2 |